2025-04-15

According to the newly revised “Preventive Test Procedures for Power Equipment”, the moisture content of SF6 switches for newly commissioned and overhauled arc extinguishing compartments shall not exceed 150ppm, and shall not exceed 300ppm during operation.

As for the harm of micro-water, the reason is obvious and will not be explained here.

We mainly explain how to reduce micro-water and meet the micro-water factory test standard.

- We must first understand where the moisture comes from?

- The equipment may be exposed to moisture during manufacturing, transportation, installation, and maintenance;

- The insulation parts of the equipment contain a small amount of moisture;

- The adsorbent itself contains moisture;

- The gas contains moisture;

- The diameter of water molecules is much smaller than that of SF6 gas molecules. Water molecules can drill into micro gaps such as micro-leakage sand holes and improper installation of sealing rings.

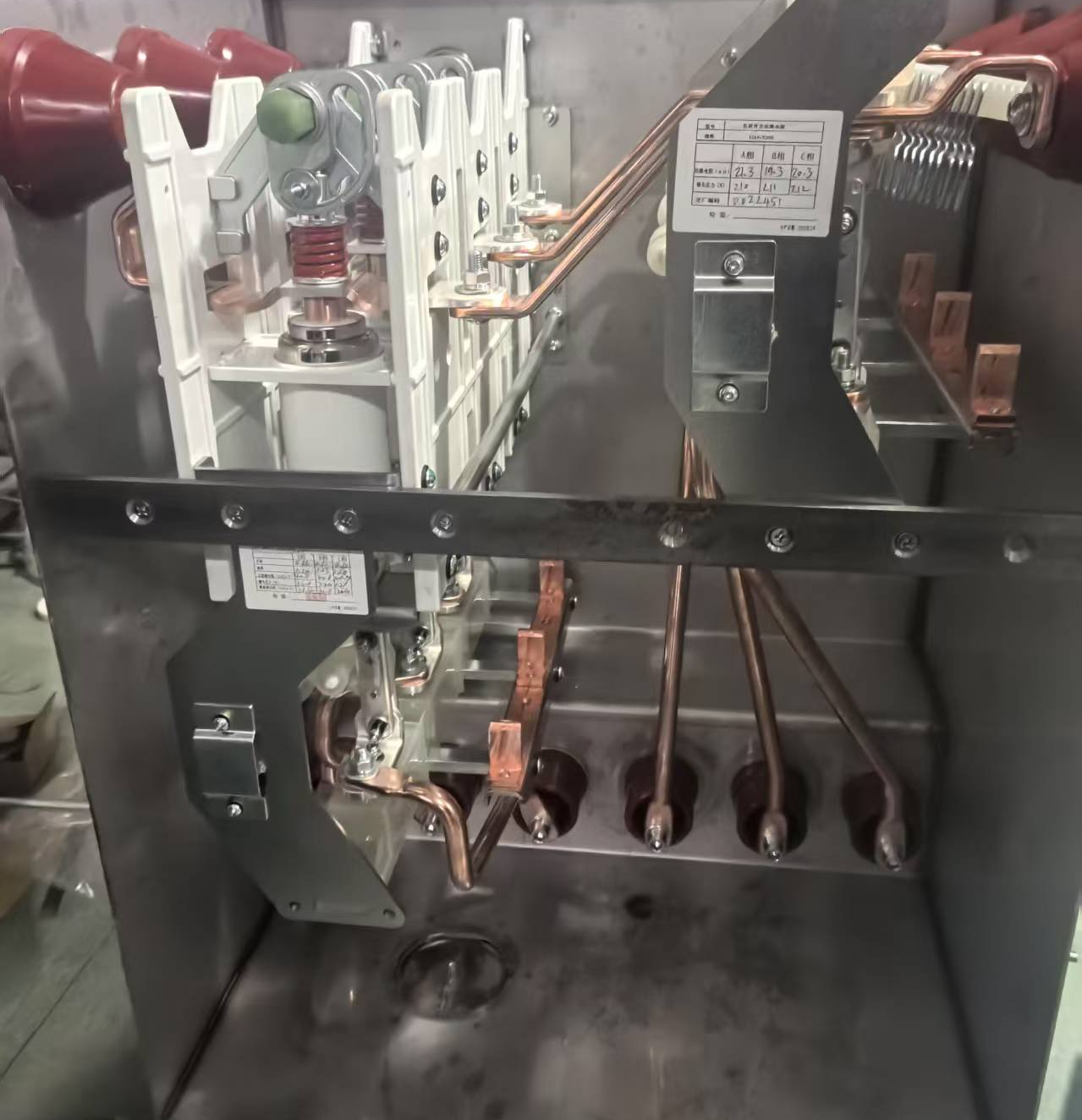

GIS cabinet gas tank without welded shell

Since they are installed in the natural environment, these parts contain a lot of moisture, especially rubber parts and plastic parts. It is difficult to remove moisture after they contain moisture. The best way to remove moisture from rubber parts and plastic parts is to dry them. It is recommended to use a dry environment as the installation workshop of the gas insulated cabinet, such as a central air-conditioning environment or a workshop on a higher floor.

Methods for removing moisture:

1.Common vacuuming methods include:

1.1. Helium leak detection vacuum chamber, the vacuum degree is generally 1000pa;

1.2. Vacuum box: Since a pointer-type vacuum gauge is generally installed, the pointer is close to “0”, which is too vague. The vacuum degree must be within the specified value.

Pointer vacuum pressure gauge

Compressor vacuuming

1.3. The most effective and professional method is the SF6 vacuum gas replenishment device. The ultimate vacuum degree of a single-stage rotary vane pump can reach 10Pa, and the theoretical ultimate vacuum degree of a two-stage rotary vane pump can reach 6.2*10-4Pa, but the flow rate is not more than 100m3/h;

Vacuum filling car

- N2 drying

The process of N2 drying is relatively simple, that is, after the gas insulated cabinet is completed, it is repeatedly filled with dry N2; the number of times of N2 filling is determined based on previous experience;

- Oven drying

This process is relatively power-consuming. The temperature and time of oven drying should be adjusted according to the practical data and experience of the enterprise’s production site and environment. The drying time and temperature should be determined according to the change of the micro-water value measured after drying;

Note: Oven drying requires baking and loading at the same time. The oven should be assembled and the inflatable cabinet should be closed and vacuumed within half an hour.

- Desiccant

Absorbs moisture through adsorbents; Activated alumina: does not absorb SF6, absorbs most of the decomposition products, has good selectivity, and is an ideal adsorbent for inflatable cabinet equipment; Molecular sieve; The moisture absorption effect of the desiccant is slowly released, and it takes several days to track and compare;

The above four methods can be combined with the micro-water value data of the initial production of the product, the change of micro-water value after process improvement, and the company’s existing equipment to consider, and finally select a process solution that is suitable for the company, relatively convenient, low-cost, reliable and stable;

We recommend trying the simplest method first:

The first mode: use vacuuming, appropriately extend the vacuuming time, and use with adsorbent; if the micro-water value after the test is close to the qualified value, it is recommended to appropriately extend the vacuuming time;

The second mode: vacuuming plus N2 drying plus desiccant;

Visual test results, increase or decrease the number of N2 drying times

If the company has a ready-made drying oven, this method can be used for testing;

Compare the above modes to find the most economical, effective and reliable solution for process curing.

Note: Each test of the trace water value should be conducted after the SF6 gas has been stationary for 24 hours. The test after N2 flushing can shorten the stationary time to about 3 hours.

The desiccant has a long adsorption time and needs to be stationary for more than 5 days to test the effect;

After the micro-water test, unqualified SF6 gas should be fully recovered and must not be discharged into the air;

Leak detection is as important as testing micro-water, and a leak detector that meets the required accuracy must be used for leak detection;