Overview

SM6 type cubicles are designed for indoor installations.

It is good for power stations and industrial electrical equipment powered by three-phase AC 50Hz/60Hz ring network or terminal It is used as load control line protection for 10kV-40.5kV MV power system. The load switch switches load current, closed-loop current, no-load transformer and cable charging current; the combined electrical appliance can break any current up to the rated short-circuit breaking current, and is suitable for complete sets of electrical equipment such as ring network units and box-type substations.

It is especially suitable for power distribution in urban residential areas, small secondary substations, switch offices, industrial and mining enterprises, large shopping malls, airports, subways, hospitals, stadiums and other places.

Their compact dimensions are: 375 mm to 750 mm wide; 1600 mm high; 840 mm deep. This makes for easy installation in small rooms or prefabricated substations.

Key Features

- Compact design and type tested.

- High level operator safety, high level operation reliability.

- Modular design allows unlimited installation possibilities.

- The lower maintenance cost.

- Suitable for remote control and monitoring.

- Comply with relevant IEC and EN standards.

Safety

- Withstand to internal arc due to durable design against thermal and dynamic effects,

- Possibility to check visually the position of Earthing Switch (CLOSE or OPEN) through the surveillance window on the front panel.

- Consecutive interlocking systems prevent incorrect operation. Access to the cable compartment and fuse compartment is only possible if the related earthing switch/switches is on the earthed position.

Fields of Major Application

- Secondary Electricity Distribution networks.

- MV/LV Distribution Transformer Substation.

- Wind & Solar Power Plants.

- Commercial Applications: Ports, train stations, airports, hospitals, schools, hotels, shopping malls, commercial centers, holiday complexes.

- Industrial Applications: water, iron and steel, automotive, oil & gas.

Technical Parameters

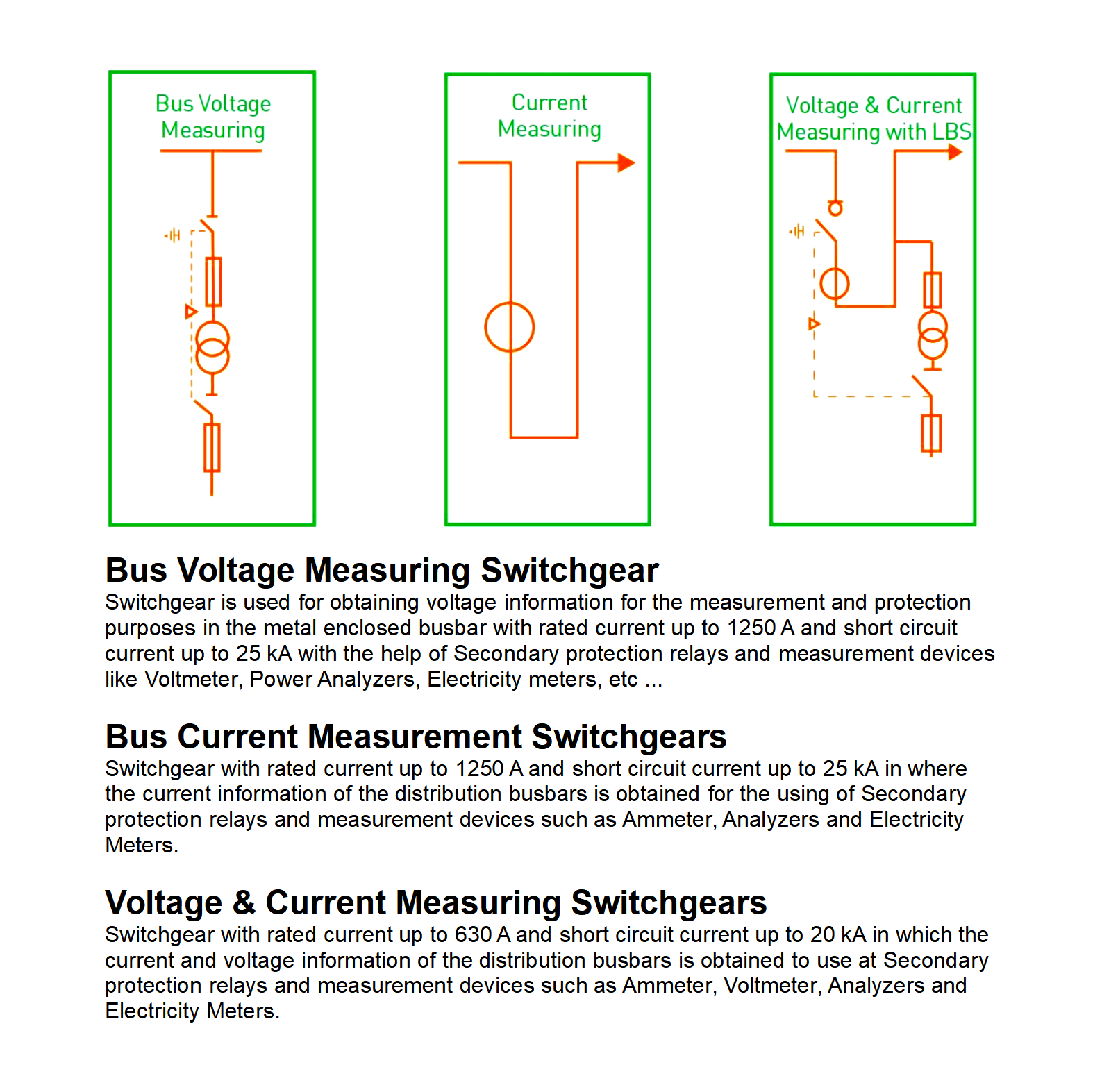

Metal Enclosed Switchgears Series One

Metal Enclosed Switchgears Series Two

Arc Extinguishing and Breaking Principle

SF6 gas has good arc extinguishing performance. In order to extinguish the arc quickly, when the switch is breaking the current, an arc will be generated when the moving and static contacts are just separated. At this time, due to the magnetic field of the permanent magnet, the arc will be driven to move quickly, causing the arc to It is elongated and continuously combined with SF6 gas to be quickly dissociated and cooled. It is extinguished when the current crosses zero. The double fracture opening distance has the insulation level of isolating the fracture. Permanent magnet rotating arc principle, small operating power, strong extinguishing ability, light contact burn, and extended electrical life.

Switch Cabinet Display

Installation and Commissioning

- Before installation and debugging, be sure to read the instruction manual carefully and make the following preparations: First, check whether there is any damage to the appearance. Damaged products should be stopped immediately. The second step is to remove contamination on the surface of the product due to transportation or other reasons.

- When the operating mechanism and the switch body are assembled, it must be ensured that they are reliably fixed, and their connecting parts should be reliably fixed on the operating shaft of the switch body, and the components connecting the load switch should also be reliably fixed on the switch body. on the switch.

- After the installation is completed, confirm that the load switch is in the opening position, insert the operating handle into the grounding operating hole on the upper end of the panel, and turn the handle 180 clockwise. To perform ground closing, rotate the handle 180 degrees counterclockwise. Complete the closing of the grounding switch.

- When performing the closing operation, first confirm that the load switch is in the opening position, then insert the operating handle into the load switch operating hole at the lower end of the panel, and rotate the operating handle 180″ clockwise to complete the closing operation of the load switch.

- During the process of moving the load switch from the closing position to the opening position, use the K-type operating mechanism, insert the operating handle into the operating hole of the load switch, and rotate the handle counterclockwise 180″ to perform the opening operation; for the A-type operating mechanism, Operating mechanism, press the opening button to open the load switch, check through the observation window whether the position of the switch is correct, and whether the corresponding observation instructions meet the requirements.

- Note: The grounding or load can only be closed when the switch is in the open position!

Maintenance and Care

Under normal use conditions where the environment meets the requirements of the installation and operation instructions, the switch body is guaranteed to be maintenance-free for 20 years. Due to environmental differences, necessary inspection and maintenance work on the load switch is still required.

- According to the working environment, conduct appropriate visual inspection of the insulation cover between June and December, and remove dirty and damp surfaces.

- Carry out lubrication and operation inspection of the operating mechanism 1 to 2 times a year to ensure normal operation.

- For load switches equipped with pressure gauges, the readings of the pressure gauges should be checked from time to time.

- When a fault current passes through the load switch fuse combination appliance and one phase fuse blows, all three phase fuses must be replaced. When replacing, the grounding switch must be closed first before replacement, and ensure that all three-phase fuses are installed in place.

◆Special Customization

The above parameters are typical data; if the existing styles do not meet your specific demands, please contact us for a custom design.We have significant personalized customization development and production skills, allowing us to provide tailored solutions to customers all over the world.