일반 정보

Radiation cross-linked heat shrinkable cable accessories are a new product in the cable industry. It has the characteristics of small size, light weight, reliable performance, strong adaptability, easy installation and low price. It is suitable for indoor and outdoor terminals, intermediate connections of various power cables (cross-linked cables, plastic cables and oil-immersed cables), as well as communication cable connections, insulation and power transmission and distribution projects in various fields.

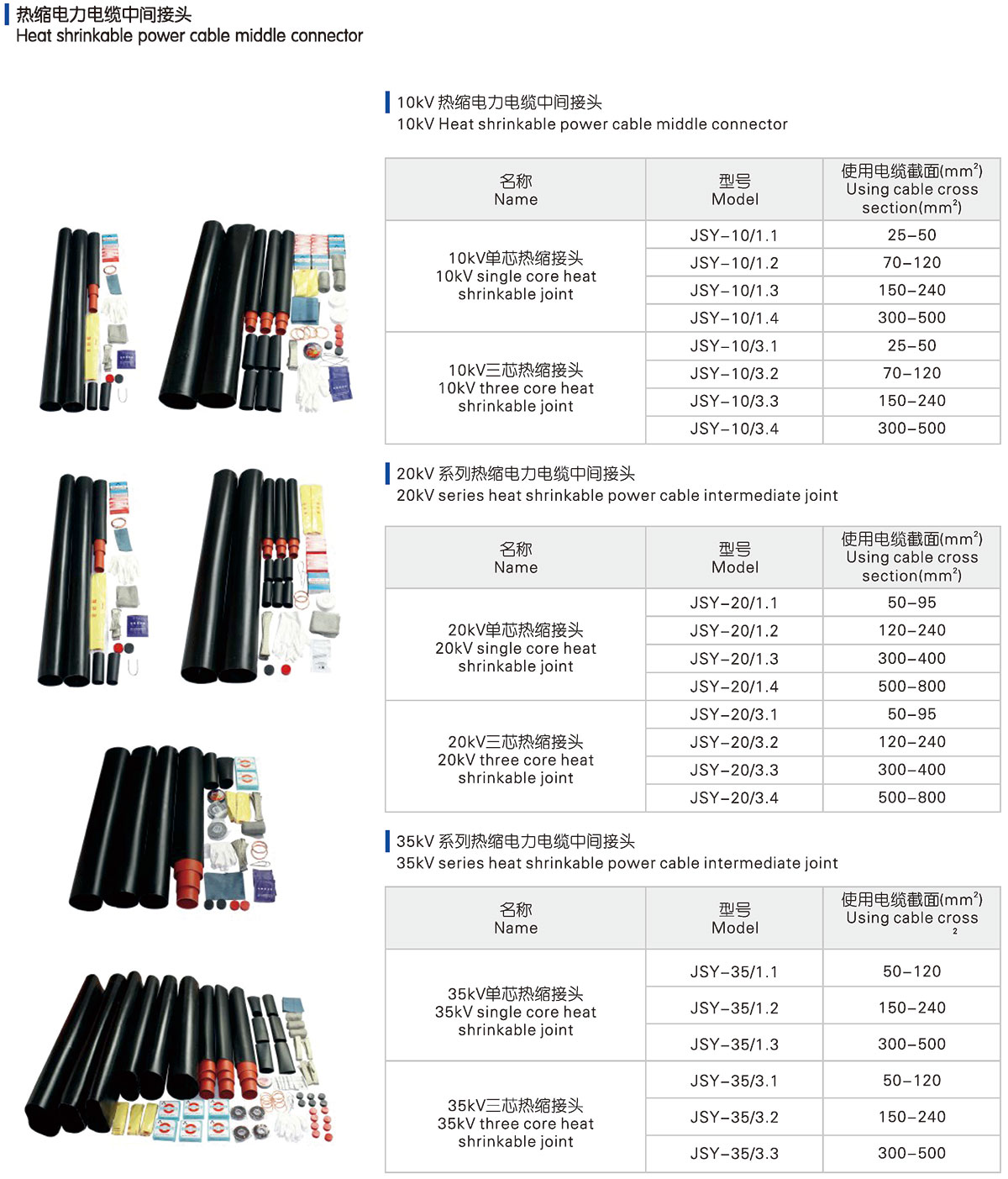

10KV, 20KV, 35KV heat shrinkable power cable terminal heads and intermediate connector series products integrate waterproofing, stress control and insulation. It has good electrical and mechanical properties and can be used for a long time in various harsh environmental conditions. It has the advantages of light weight and easy installation. Widely used in electric power, petrochemical industry, metallurgy, railway ports and construction fields.

Heat shrinkable cable accessories, commonly known as heat shrinkable cable heads, are widely used in the intermediate connections and terminals of cross-linked cables or oil-immersed cables with voltage levels below 35KV and below. Compared with traditional cable accessories, it has the characteristics of small size, light weight, safety and reliability, and easy installation. The product complies with the GB11033 standard. The long-term use temperature range is -55℃~105℃, the aging life is up to 20 years, the radial shrinkage is ≥50%, the longitudinal shrinkage is <5%, and the shrinkage temperature is 110℃~140℃.

The materials used are generally composed of blends of various material components such as polyethylene, ethylene vinyl acetate (EVA), and ethylene-propylene rubber.

This type of product mainly uses stress tubes to deal with the problem of electrical stress concentration. That is to say, the parameter control method is used to alleviate the electric field stress concentration.

The main advantages are light weight, easy installation and good performance. cheap price.

Stress tube is a heat shrinkable tube with special electrical parameters with moderate volume resistivity (1010-1012Ω·cm) and large dielectric constant (20–25). It uses electrical parameters to force the stress evacuation at the cable insulation shielding fracture. into a more even distribution along the stress tube. This technology can only be used in cable accessories of 35kV and below. Because the stress tube will heat up and cannot work when the voltage level is high.

The key technical issues in its use are: To ensure that the electrical parameters of the stress tube must reach the values specified in the above standards before it can work. In addition, attention should be paid to filling the air gap at the fracture of the cable insulation semi-conductive layer with silicone grease to eliminate gas and achieve the purpose of reducing partial discharge. Cross-linked cables will shrink greatly during operation due to poor internal stress treatment. Therefore, when installing accessories, pay attention to the overlap between the stress tube and the insulation shield by no less than 20mm to prevent the stress tube from being separated from the insulation shield during shrinkage.

Due to the low elasticity of heat-shrinkable accessories, air gaps may occur at the interface during thermal expansion and contraction during operation, so sealing technology is very important to prevent moisture from infiltrating.

◆스페셜 커스터마이징

위의 매개변수는 일반적인 데이터입니다. 기존 스타일이 귀하의 특정 요구 사항을 충족하지 못하는 경우 맞춤형 디자인을 위해 당사에 문의하십시오. 우리는 중요한 맞춤형 맞춤형 개발 및 생산 기술을 보유하고 있어 전 세계 고객에게 맞춤형 솔루션을 제공할 수 있습니다.