2024-12-12

When the high-voltage circuit is disconnected, the voltage will break down the air to produce high-temperature and high-conductivity free gases, which appear as instantaneous high-temperature sparks, which are arcs.

The damage of arc is very high: the arc will generate high temperature, which will ablate the surface of the contact and burn out the insulating material. The two originally disconnected contacts formed a current due to the presence of arc, which prolonged the time for the switch to disconnect the circuit and aggravated the damage caused by short circuit faults in the power system. Arcs can cause fires or even explosions.

Therefore, arc extinguishing has become an important link in high-voltage electrical equipment. Take the ring main unit as an example. It needs to complete the switching of high-voltage circuits, and it must be placed in densely populated areas such as airports and residential areas. Its safety must be ensured.

To eliminate arcs, traditional methods mainly include the following ideas:

- Drop the Voltage.

Speaking of reducing voltage, some people hope to directly reduce the voltage in the circuit, but this is obviously not possible. After all, what the equipment needs to do is to complete the disconnection of the circuit during high-voltage transmission. It cannot always change high-voltage transmission to low-voltage transmission. The drop voltage here is the voltage at the moment when the drop contact is disconnected! We know that U=IR, when the contact is disconnected, R will increase instantly. If we want to minimize U, we should ensure that the current flowing through the contact is minimum at the moment when the contact is disconnected. Also note that in AC circuits, the current and voltage zero crossings are often not synchronized, depending on the type of load.

To minimize the voltage at the contact when the contact is open, ensure that the action occurs when the current crosses zero. So ideally, I is exactly 0, U=IR=0, so no arc will occur. But this is not the case. This idea is difficult. The difficulty is that a mechanical structure must operate accurately on a 50Hz current. Compared to the rapid changes in current (50Hz), the mechanical contacts move too slowly. More importantly, the time difference between the two actions is also different! This time you trigger it, it disconnects after 15ms, and the next time you trigger it, it disconnects after 22ms. This jitter range is very important under the current of 50Hz.

- Air Blowing to Extinguish the Arc.

After the arc is generated, the arc can be extinguished by air blowing, which is what we often call arc blowing. Arc blowing uses airflow to act on the arc, which can effectively cool the arc, increase the pressure in the arc zone, and take away residual free gas, so it has good arc extinguishing performance. The arc blowing method can be horizontal blowing or vertical blowing.

Moreover, some grids can be added around the part where the arc is generated, so that the arc can be cut off. This helps to quickly extinguish the arc.

Of course, extinguishing the arc is not about finding someone to blow on. The air flow generated by the contact action can be used to complete the arc blowing operation.

Under normal circumstances, most arc blowing methods are used. After all, the implementation cost of this method is not high. For example, various arc extinguishing chambers will have arc blowing mechanisms and grids.

- Replace the Media.

If we replace the medium with better insulating properties and break the circuit in this medium, the arc can be reduced. The easiest thing to think of is vacuum. The arc extinguishing effect of vacuum interrupter is very good, but the cost of vacuum is high and its life is short.

The most commonly used medium now is sulfur hexafluoride SF6. It is a synthetic gas that was synthesized 100 years ago by two French chemists, Moissan and Lebeau.

Sulfur hexafluoride has the following characteristics:

The high thermal conductivity can quickly conduct the temperature of the arc away. It is colorless, odorless, non-toxic, has stable chemical properties, and is not prone to chemical reactions at room temperature. Therefore, sulfur hexafluoride is widely used in the power industry as an insulation and breaking medium for medium and high voltage electrical equipment. However, sulfur hexafluoride is a greenhouse gas and has a global warming potential (GWP) of 23,500, which means that 1 kilogram of sulfur hexafluoride has the same impact as 23,500 kilograms of carbon dioxide. This is very serious.

Are there any solutions that are safe, environmentally friendly, and have a long lifespan?

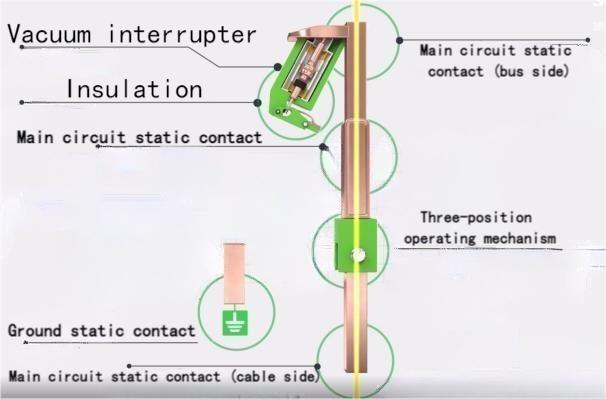

- Parallel Vacuum Interrupting (SVI) Solution.

This is a safer and more environmentally friendly solution, first proposed by Schneider Electric and used in ring main units. The parallel vacuum interrupting solution consists of a vacuum arc extinguishing chamber and an isolating switch in the air, which realizes the common three-station switch operation with a small number of parts and low cost.

Let’s take Schneider Electric’s solution as an example to introduce the principle of SVI.

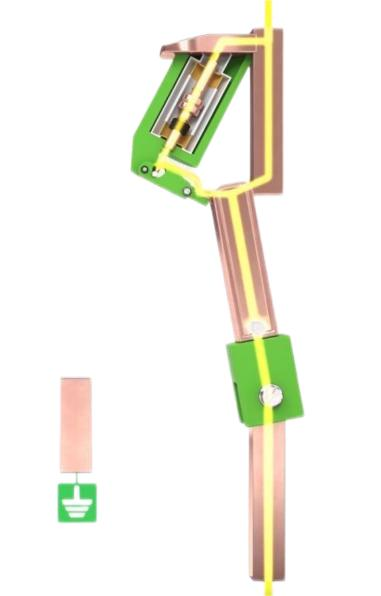

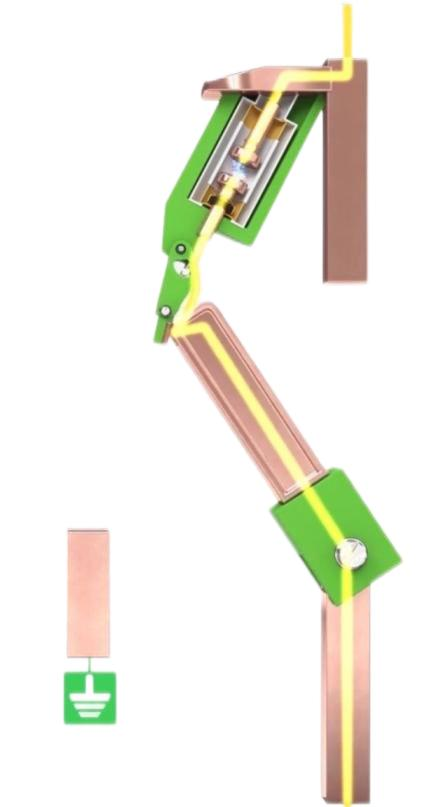

When the moving contacts move, current is transferred from the stationary contacts to the vacuum interrupter. And it should be noted that at the moment when the moving contact and the static contact are separated, because the contacts are at the same potential, no arc will occur.

The current then passes through the vacuum interrupter in the closed position. Next, driven by the movable contact, the pivot rod rotates and drives the vacuum interrupter to open and close.

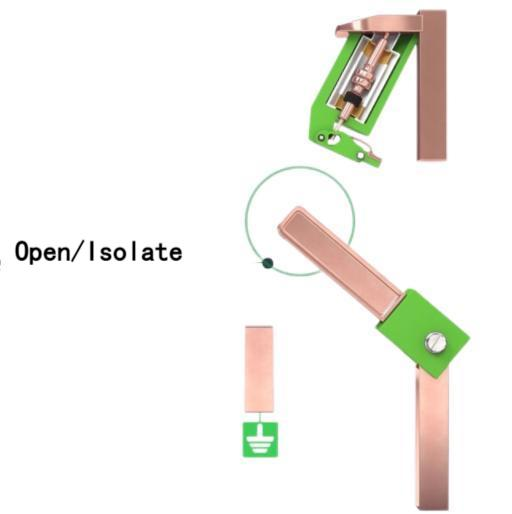

When the current interruption is completed, the moving contact releases the pivot rod and continues to rotate to the isolation position. Under the action of the buffer spring, the pivot rod returns to its original position, thereby closing the vacuum interrupter.

This solution can reduce the size and cost of the vacuum interrupter. Because the vacuum interrupter only works in the breaking stage, it will withstand the transient recovery voltage during breaking, but it does not need to have short-circuit closing capability, short-term current withstanding capability, and continuous current withstanding capability. During the closing phase, the current does not pass through the vacuum interrupter. Moreover, during the breaking phase, the time for the current to flow through the vacuum interrupter is only a few millimeters.

In the isolation state, the moving contacts and the stationary contacts are isolated in dry air.

As a medium in isolation, dry air has the following advantages:

Non-toxic and safe for operators. You can rest assured that the equipment is installed near public places without worrying about toxic gas leakage.

It is pollution-free, replaces sulfur hexafluoride and avoids the greenhouse effect.

It is easy to use. When the equipment is scrapped, the gas does not need to go through a complicated recovery process and can be released directly.

It can be seen that parallel vacuum interrupting has advantages and is likely to replace the sulfur hexafluoride solution.

Moreover, we found that the entire process was operated in the same manner as the currently used three-position sulfur hexafluoride switch: one operation to achieve breaking/isolating, and the second operation to achieve grounding. Even Schneider Electric’s ring main unit solution has the same footprint as the sulfur hexafluoride switch, and even the height of the busbar copper bars and cable joints remains unchanged. It can be easily modified and the original The sulfur hexafluoride scheme was transformed into a new scheme. So it is a more environmentally friendly and safer solution.